1. Cov lus piav qhia txog hom khoom ntim graphite

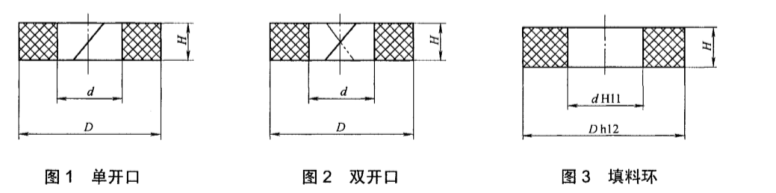

Muaj 3 hom fillers hauv qab no uas feem ntau siv rau hauv:cov li qub

Cov khoom siv rau hauv qhov project no yog hom qhib ib zaug hauv Daim Duab 1 thiab cov khoom zoo li lub nplhaib hauv Daim Duab 3. Cov duab tiag tiag yog raws li nram no:

Daim Duab 1 Hom ntim khoom qhib ib zaug xwb

Daim Duab 3 Lub nplhaib ntim khoom

Cov haujlwm siv ntawm ob lub pob saum toj no zoo ib yam, qhov sib txawv nyob rau hauv cov xwm txheej siv sib txawv. Lub pob qhib ib zaug yog qhov tsim nyog rau kev hloov cov pob thaum lub sijhawm saib xyuas lub valve txhua hnub. Cov pob tuaj yeem hloov online, thiab lub nplhaib ntim khoom yog qhov tsim nyog rau kev kho lub valve. Siv rau kev rhuav tshem thiab kev saib xyuas.

2. Kev piav qhia txog cov yam ntxwv ntawm graphite packing

Raws li cov kev cai ntawm kev tsim cov khoom sau, cov khoom sau yuav tsum muaj qee qhov kev ywj pheej, yog li yuav muaj kev ywj pheej los ntawm sab hauv mus rau sab nraud tom qab kev sau tiav. Ob hom graphite fillers uas tau hais los saum toj no yog cov khoom sau braided uas nws cov txheej txheem molding yog braided los ntawm ntau cov fibers graphite, thiab qhov ywj pheej raug nqus los ntawm qhov sib txawv braided thiab tsis muaj qhov pom tseeb ntawm kev ntshaw rau kev nthuav dav. Ntim nplhaib-hom ntim graphite yog cov khoom ntim me me nrog sab hauv me me. Tom qab lub sijhawm ntev ntawm kev sawv, qhov ywj pheej sab hauv yuav qhia cov kab nrib pleb ntawm qhov chaw ntawm cov khoom ntim thiab tso tawm qhov no ntawm kev ntxhov siab. Hom khoom sau no yuav nyob ruaj khov thiab tsis hloov pauv tom qab qee qhov tawg tau tsim. Thaum nws raug nias dua, qhov tawg ploj mus thiab qhov rov qab ua tau raws li qhov yuav tsum tau ua.

Cov hauv qab no yog cov kev cai rau cov nplhaib graphite yooj ywm

Rooj 2 Kev ua tau zoo ntawm lub nplhaib ntim khoom

| kev ua tau zoo | chav tsev | cov ntsuas | ||

| Ib qho graphite yooj ywm | Cov hlau sib xyaw ua ke | |||

| lub foob | g/cm³ | 1.4~1.7 | ≥1.7 | |

| Qhov sib piv ntawm kev sib zog | % | 10~25 | 7~20 | |

| Tus nqi rov qab los | % | ≥35 | ≥35 | |

| Kev poob phaus thermal | 450 ℃ | % | ≤0.8 | —- |

| 600 ℃ | % | ≤8.0 | ≤6.0 | |

| Kev sib txhuam coefficient | —- | ≤0.14 | ≤0.14 | |

| a Rau cov hlau sib xyaw, thaum lub ntsiab lus yaj ntawm cov hlau qis dua qhov kub sim, qhov kev sim kub no tsis haum. | ||||

3. Txog kev siv cov khoom ntim graphite

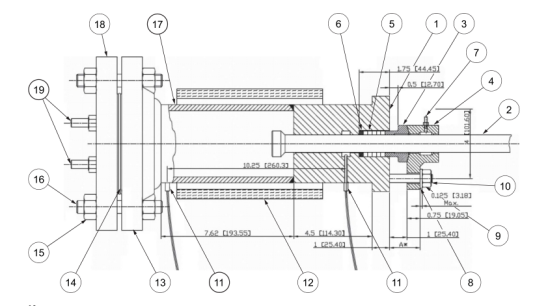

Cov graphite packing siv rau hauv qhov chaw kaw ntawm lub valve stem thiab lub packing gland, thiab cov packing yog nyob rau hauv lub xeev compressed thaum lub sijhawm ua haujlwm. Txawm hais tias nws yog ib hom qhib ib zaug lossis ib hom ntim nplhaib, tsis muaj qhov sib txawv hauv kev ua haujlwm ntawm lub xeev compressed.

Cov hauv qab no yog daim duab qhia txog lub xeev ua haujlwm ntawm kev ntim khoom (daim duab qhia txog kev sim ntim khoom)

Lub sijhawm tshaj tawm: Lub Xya Hli-12-2021